You need a trusted partner to navigate your complex challenges. Let’s achieve your goals together.

Whether you're embarking on the transition to 300mm wafer technology, strategizing for a new solar manufacturing facility, or simply aiming to optimize your facility for future adaptability, we're here to support you every step of the way. Customers choose Mortenson because, no matter the difficulty of the project, we deliver.

Capabilities Across Sectors

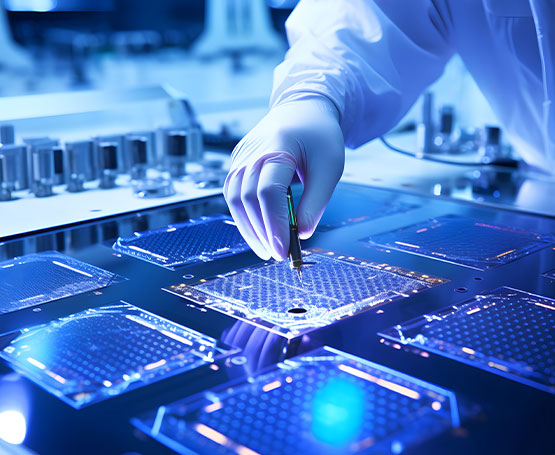

Our expertise spans advanced manufacturing, encompassing cutting-edge technologies such as automation, cleanrooms, high-purity gas/chemical delivery systems, advanced materials, and intricate engineering processes. These capabilities empower us to drive manufacturing innovation across diverse sectors including aerospace, energy, semiconductors, microelectronics, biotechnology, pharmaceuticals, automotive, medical devices, and chemicals.

Geographic Support

Supported by key geographic regions in major cities across the country, our national advanced manufacturing team is available to assist you in delivering what lies ahead. Whether it's constructing solar manufacturing facilities in the south and southeast or seizing semiconductor opportunities in established geographies, our team stands ready with proven develop-design-build solutions to bring your vision to fruition. With Mortenson by your side, you can confidently embrace what lies ahead, knowing that we're dedicated to delivering what's next.

100+

ADVANCED MANUFACTURING PROJECTS IN THE U.S.

23

FACILITIES LARGER THAN ONE MILLION SQUARE FEET

$2.5B+

IN SEMICONDUCTOR & ADVANCED MANUFACTURING PROJECTS

30

YEARS BUILDING ADVANCED MANUFACTURING FACILITIES

Partnering and Project Success at Woodward

“Mortenson was in this with us. They gave me a ton of confidence and helped us deliver this excellent campus.”

STEVE STIESMEYER

DIRECTOR OF REAL ESTATE

WOODWARD, INC.

Avoid Unexpected Costs of Automation

Case Study: As a manufacturer planned to upgrade equipment, assessment findings protected a capital plan from a 300% overrun

Wondering Where To Begin With Your Project?

From optimizing lines and laying out equipment for better flow, to reducing energy costs and solving for deferred maintenance, consolidating space or developing a greenfield project, we’re here to ensure you get the most for your investment.