VDC in our DNA

For nearly 20 years, our team has helped pioneer the use of Building Information Modeling (BIM) and Virtual Design and Construction (VDC) in all phases, from preconstruction through operations and maintenance. As measured by McGraw Hill, the longer a firm has invested in the use of BIM, the greater the impact to its partners and customers. Our innovation-based culture has led us to develop an experience level that is simply unparalleled in the industry.

The early days of VDC

In 1995 Mortenson formed the Center for Construction Innovation to research ways to improve construction processes and technologies. Inspired by emerging 3D-graphics technologies in the manufacturing and aerospace industries we began to see the potential of computer-generated graphics as they related to our own industry. Something big was on the horizon.

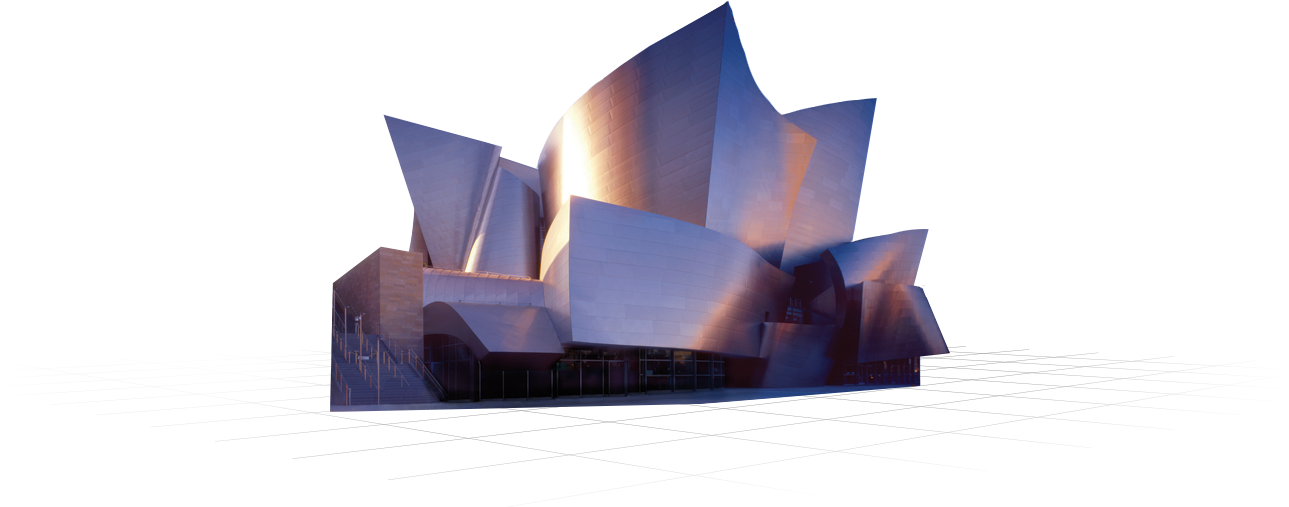

We built the “unbuildable.”

Working with Stanford University and Disney Imagineering, a team from Mortenson was about to make history. Building the Walt Disney Concert Hall in Los Angeles would have been next to impossible using conventional construction processes. Virtual Design & Construction (VDC) gave engineers the detail needed to make such a complex design a reality. This was only the beginning.

(Los Angeles, CA)

Building and installing an acoustic ceiling

Using Building Information Modeling, the project team determines how to create and install the complex prefabricated ceiling panels over the stage in the Walt Disney Concert Hall.

4D Models developed

Mortenson's growing team of VDC experts develop the first 4D models, which incorporate time into the three-dimensional model.

Computer Numerical Controls

Our project teams begin to use our models to drive CNC (computer numerical controls) fabrication of building systems based on the 3D project database

Putting know-how to action.

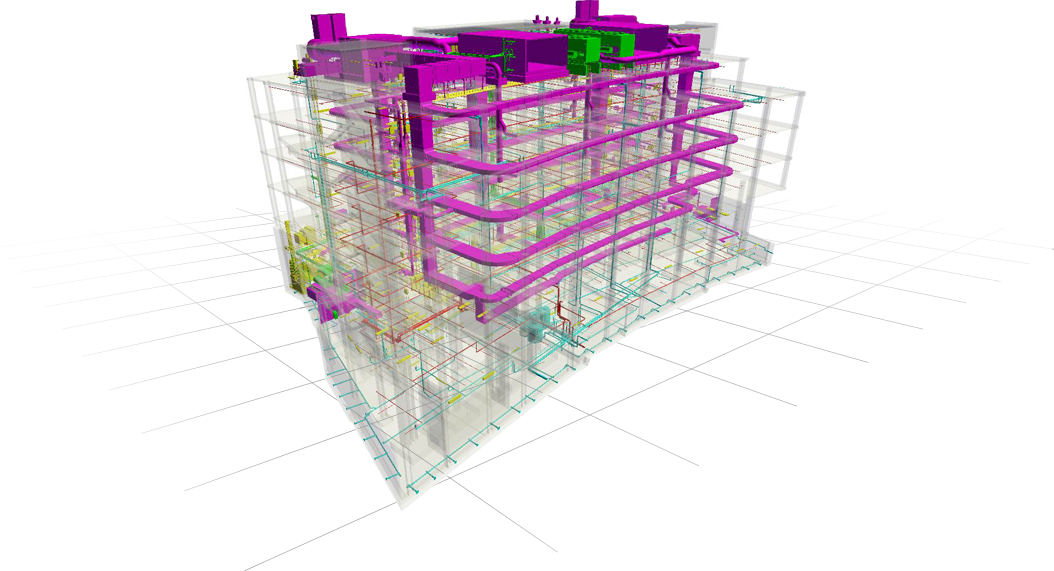

With the onset of model-based clash detection in 2001, spatial conflicts could be detected and eliminated before construction even began—a breakthrough for team coordination and a reduction in scheduling delays. Our Integrated Delivery Advancement Team was now promoting companywide development of VDC. An early output of this team was our new plan-room computers that brought vital information onto the construction site, putting modeling data into the hands of craftworkers.

(Denver, CO)

Model-based Clash Detection

Mortenson begins the use of model-based clash detection. We start to establish processes to lead and manage “total building” coordination and planning

Expert Advisory Board Formed

Mortenson forms a company-wide think-tank called the Integrated Delivery Advancement Team (IDAT) to further Mortenson team member knowledgebase and expertise in virtual design & construction.

First Model-based Prefab

We build our first model-based prefabricated wet core, allowing us to build components of a lab building off-site to improve quality and reduce the project schedule.

A collaborative, integrated approach.

The mid-2000s saw significant steps forward when it came to fine-tuning VDC best practices and increasing project communication and collaboration. Along with 3D models and “fly-throughs,” project web sites enabled a new way of interacting with stakeholders at projects like the Benjamin D. Hall. This design-build-operate-maintain building earned Mortenson an AIA TAP Building information modeling award.

Interdisciplinary Research Building

(Seattle, WA)

Sharing Lessons Learned

Mortenson deploys internal collaboration tools to capture and share virtual design & construction lessons learned companywide, and further our VDC knowledgebase.

Journey to The Last 100 Feet®

Integrated Work Plans (IWP) are deployed on our project sites – assembling all of our project model database information into simple, comprehensive “instruction sets for the field”, thus beginning our journey to The Last 100 Feet®.

Second R&D Benchmark: Boeing

Mortenson's research & development efforts continue as we study lean principles and prefabrication research in the commercial airplane manufacturing process and its application to the construction process.

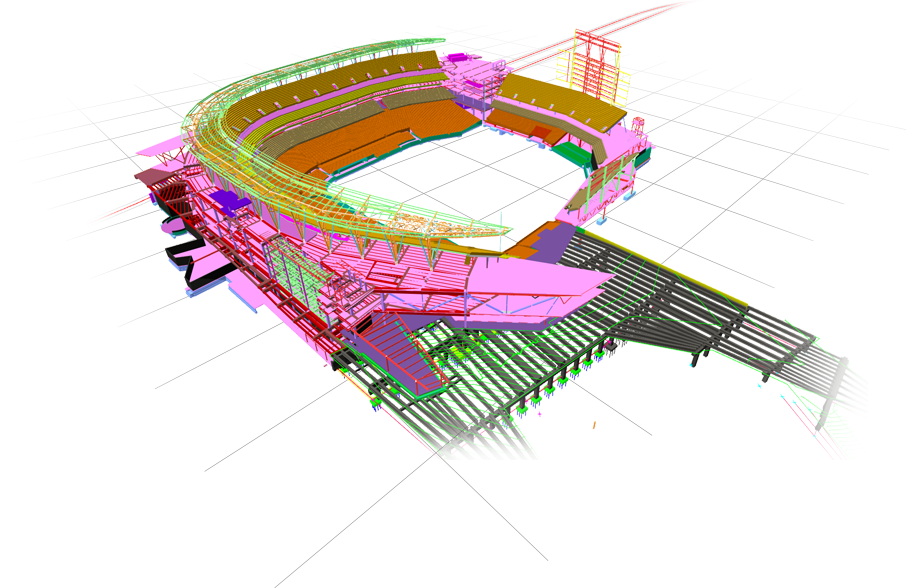

A unified game plan.

What would happen if we made project plan data and real-time analysis available to every worker on a construction site? This question drove Mortenson’s “Last 100 Feet®” initiative, which made use of new Digital Plan Tables, tablets, and Plan of the Day (POD) workstations. Not only was VDC enabling the building of structures which were once unthinkable, like Target Field in Minneapolis, MN, but building information modeling was now improving the management of facilities post-construction.

The Last 100 Feet® in Action

Mortenson introduces the concept of The Last 100 Feet®, which moves VDC from a computer in an office directly into the field, driving efficiency and innovation further into the project site.

Developing Our First "Virtual Mockups"

Mortenson project teams develop our first enclosure “virtual mock-ups, ” which are detailed enclosure models that allow our teams to build virtually before we build physically.

Fourth AIA BIM Award

Mortenson receives its fourth AIA TAP award for Design/Delivery Process Innovation using Building Information Modeling. Awarded projects include UoW BDH Interdisciplinary Research Building (2007), UCHSC Research II (2009), EKG Cornerstone Art Center (2009).

VDC as standard practice

By this time, VDC was Mortenson’s way of doing business, influencing each phase of every project, but most importantly our project stakeholders. We formalized our “40 to 400” initiative to make VDC central to how we build, so each project team member would be able to leverage VDC to plan and build smarter to drive higher value to our customer. As a downstream result, we began VDC knowledge transfer to our renewable energy and horizontal markets. VDC is not just for buildings anymore.

Fifth AIA BIM Award

Mortenson receives its fifth American Institute of Architects Building Information Modeling Award for Design/Delivery Process Innovation using BIM at The Medical Center (confidential customer). At this time, Mortenson Construction is the only general contractor to win five individual AIA BIM awards.

Model-based Estimating

Model based estimating systems are rolled out as a company-wide solution for improved preconstruction and integration with design partners.

Touch Screens

Touch screens are integrated into our Plan of the Day (POD) and Plan Room Computer (PRC) stations on project sites – further enabling ease of use and access to our models.

Modern-day pioneers.

Today, Mortenson stands apart as industry frontrunners in VDC and BIM, enabling projects to be completed more quickly and at lower costs than ever before. With virtual reality systems, our customers can now experience projects before they are even built—helping them make better, more informed decisions. We’re already looking onward to tomorrow’s possibilities.

VDC Project Analysis

This study was completed as part of a research consortium between the University of Minnesota and Mortenson Construction, the Master of Science in Architecture Research Practices (MS-RP) program.

Read more...

AR / VR

Mortenson takes the design phase process to an immersive CAVE experience providing our design partners and customers with a new enhanced decision making solution.

See Inside Pegula Ice Arena

Read 2014 AIA TAP Award Study

Renewable Energy BIM Award

In 2012, Mortenson expands their BIM awards to the renewable energy industry. The Spring Valley Wind Farm wins the Bentley Be Inspired Awards for Innovation in land development, engineering, and management.

The road ahead

At Mortenson, we are continually improving our process and looking for new ways to leverage technology to improve our people and process. We focus on industry and academic partnerships to drive VDC research to building what’s next. Stay tuned for more as we work together to change the landscape of what’s possible today to be prepared for a better tomorrow.

SEE WHAT'S COMING NEXT